The company

We think

in terms of generations

Paul Köster GmbH is a family company with a long history, based in Medebach in the Sauerland region of Germany. The company’s history spans more than 100 years, and our focus is on consistency and outstanding quality. Special mechanical engineering is our area of expertise and our passion.

We take a long-term approach – not only when it comes to the generations that run the company, but also in the generations of machines we build. And, thanks to their modularity and solid construction, our machines are compatible with several generations of components and production processes.

The machine concept

A MACHINE FORGENERATIONS

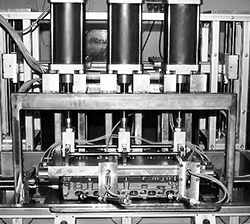

Our machines are durable, precise and flexible. The modular construction of our testing systems, consisting of the base machine and fixture, allows for effective retooling and retrofitting for use in different testing processes, as well as adaptation to new components. The robust construction of all components ensures that our machines require little maintenance and operate reliably, even when in constant use in an industrial setting.

Along with the equipment mounts and frame, the base machine includes the control unit, the electrical cabinet and the hydraulic unit. It can be used to operate a variety of test fixtures, which can be flexibly installed as required.

Each test fixture is specially adapted to a specific component and process. Different fixtures can be used by setting-up in a single base machine as required.

1. PRECISION

From sealing concepts to mechanics and consumables, we offer consistent quality. Because a testing machine only fulfills its purpose if it constantly and reliably provides results of the highest precision. Our in-house production with high vertical integration ensures it.

2. DURABILITY

Precision also depends on the materials used. It is important to us that our machines are long-lasting and robust, and keep running like they did when they left the factory, even after long periods of use.

3. MODULARITY

Our long-lasting base machines can be retooled and retrofitted with a variety of test fixtures. That allows the system to be easily adapted to changes in the production process, new components and different testing procedures.

The PK principle

Precision is our passion.

100%

… precision is the measure of all things. A component is only used if it meets the highest standards. And the same applies to our testing machines, which must offer the highest levels of precision in all testing methods. We ensure both.

200%

… enthusiasm for our work comes naturally to us. We give 200% for every machine, process and task. Whether in design, production or service – we give it our all. Because our work is our passion.

Management

Paul Köster is not just a name.

“Paul Köster GmbH is a family company through and through. That is not only reflected by the company’s name, but throughout the entire company. We know that each individual makes a contribution to the success of the company, and, of course, as Managing Directors we have a lot to live up to. While that may be considered special at other companies, it is absolutely self-evident for us.” – Friedrich Köster

The brothers Paul, Friedrich and Ernst Köster have been the Managing Directors of Paul Köster GmbH since 1991. Together, their enthusiasm, passion and total commitment have made the Medebach-based company, which is steeped in tradition, an international success story. From 2022, the management will now gradually begin to be handed over to the third generation, starting with Christopher Köster.

Milestones

- Family company established when an old forge was taken over by Wilhelm Studen and his wife Wilhelmine, née Köster.

1956

Company was taken over by Paul Köster, Sr. and his wife Elfriede.

1979

Initial activities in the field of general mechanical engineering for Continental in Korbach, Germany.

1986

First entry into the field of leak testing with the construction of a leak testing machine for cylinder heads.

1991

Paul, Friedrich and Ernst Köster take the reins at the company.

1992

Construction of the new premises on an industrial estate in the town of Medebach, Germany. At the time the company had 35 employees.

1993

Foundation of the company SMM Sondermaschinenbau Medebach GmbH in the field of woodworking machines.

2007

Subsidiary LK established in Suzhou, China.

2014

Cooperation begins with DMV Sondermaschinenbau in Bad Arolsen, Germany.

2015

Foundation of the company Albrecht Sondermaschinen GmbH in Nordhausen.

2018

Formation of the company BETH Sondermaschinen GmbH in the field of woodworking machines. (Former SMM Sondermaschinenbau Medebach GmbH.)

2019

390 employees worldwide, project volume of EUR 1,000 to EUR 5 million, 15,000 m² of production space in Germany and approx. 2,000 m² in China

2022

Successive handover of management to the 3rd generation, starting with Christopher Köster.

COMPETENCE

Our customers

We serve countless customers from the automotive sector and other industries.

A small representative selection is presented here.

Friedrich Köster, Managing Director

Head of Sales

Ernst Köster, Managing Director

Head of Mechanical Engineering & Service

Jürgen Köster, Managing Director

Head of Fixture Construction

Christopher Köster, Managing Director

Sales & Head of IT

Behind the Scenes

Virtual Tour

Among our customers, the company tour is very popular as an integral part of the inquiry process. However, as we have a lot of international customers, the trip to Medebach is not always possible without major effort. That's why we created a virtual company tour in spring 2020, which is intended to provide an authentic insight into our daily work – digitally and available worldwide.

With the help of state-of-the-art technology, we can present a total of 21 important company areas in realistic 360° images and show the entire project phases of an order. Interactive elements combined with complete freedom of movement within the application make this company tour an entertaining alternative.

We invite you to take a look behind the scenes, optionally together with one of our sales colleagues, just give us a call!

Group of companies

Our partners

SUZHOU LK SPECIAL AUTOMATION EQUIPMENTS LTD.

Suzhou LK Special Automation Equipments Ltd. is an independent subsidiary of Paul Köster GmbH and serves the demand from the rapidly growing Asian market.

DMV SONDERMASCHINENBAU GMBH

DMV Sondermaschinenbau GmbH is your partner with roots in the medical technology industry and particular expertise in the area of special mechanical engineering, with a focus on automation and assembly technology.

ALBRECHT SONDERMASCHINEN GMBH

Albrecht Sondermaschinen GmbH offers support in all areas of special mechanical engineering, from construction to maintenance, with tailored solutions for your specific needs.

BETH SONDERMASCHINEN GMBH

BETH Sondermaschinen GmbH is a competent, reliable partner in the field of special mechanical engineering particularly for wood machining and aluminum processing.